Everything That’s Inside Your iPhone

Credit to Author: Brian Merchant| Date: Tue, 15 Aug 2017 16:51:59 +0000

This article is adapted from The One Device: The Secret History of the iPhone. Apple said it stopped working with some metal suppliers after the book detailed those suppliers’ poor labor practices; this passage includes new reporting detailing the outcome of those changes in Apple’s supply chain.

The iPhone is many, many things. With its immaculate design, gleaming screen, and reigning station as our daily work/life navigator, it’s relatively easy to forget that the iPhone is still ultimately a composite of dredged-up earth. Before it is anything, it’s rock, it’s metal; it’s raw elements. A lot of them. Over the course of a two-year effort to get to the soul (and guts) of what Steve Jobs called the “one device,” I aimed to trace the device to its deepest roots. And that meant trying to glean what the iPhone was actually composed of at its most foundational levels. It meant trying to determine the precise elemental composition of the iPhone. So, I asked David Michaud, a mining consultant who runs 911 Metallurgist, to help me pulverize one to dust in a rock-crusher, while measuring the escaping gases in the process.

That’s how it came to pass that I bought a brand-new iPhone 6 at the flagship Fifth Avenue Apple Store in Manhattan in June of 2016, and shipped it to Michaud. He in turn sent it to scientists at a metallurgy lab, who performed the following tests:

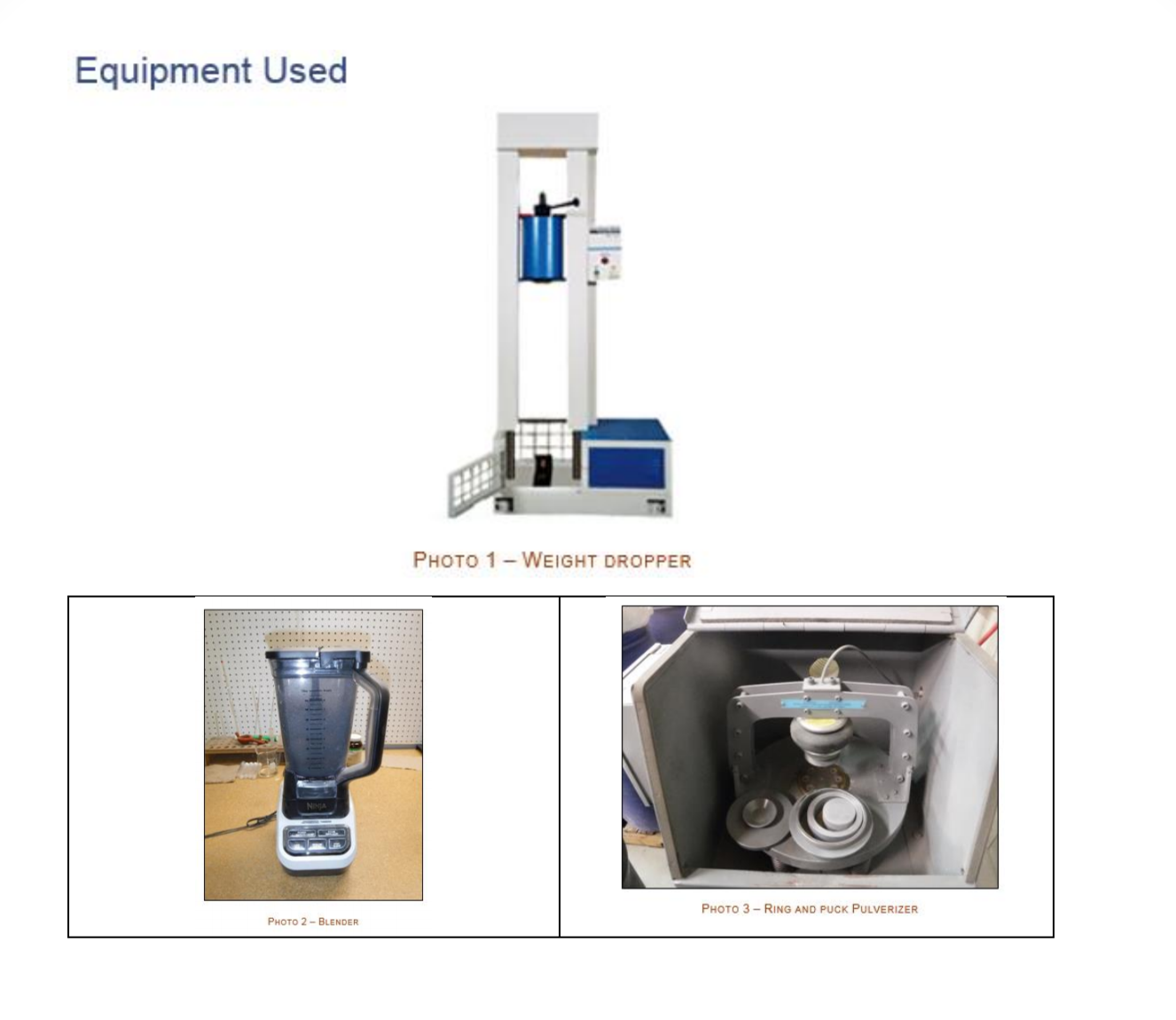

First, they weighed the device—129 grams, just as Apple advertises. The iPhone was set inside an impact machine used for pulverizing rock, where, in a contained environment, a 55-kilogram hammer was dropped on it from 1.1 meters above.

Naturally, the lithium-ion battery caught fire. The entire mass of the phone was then recovered, and placed in an industrial blender. Efforts to break it down inside said blender did not go so well—so it was screened, separated, and broken down in a ring and puck pulverizer until the material was a fine powder. “It surprised me how difficult it was to destroy,” Michaud said.

“The non-metallic components were combined with the screen undersize and were

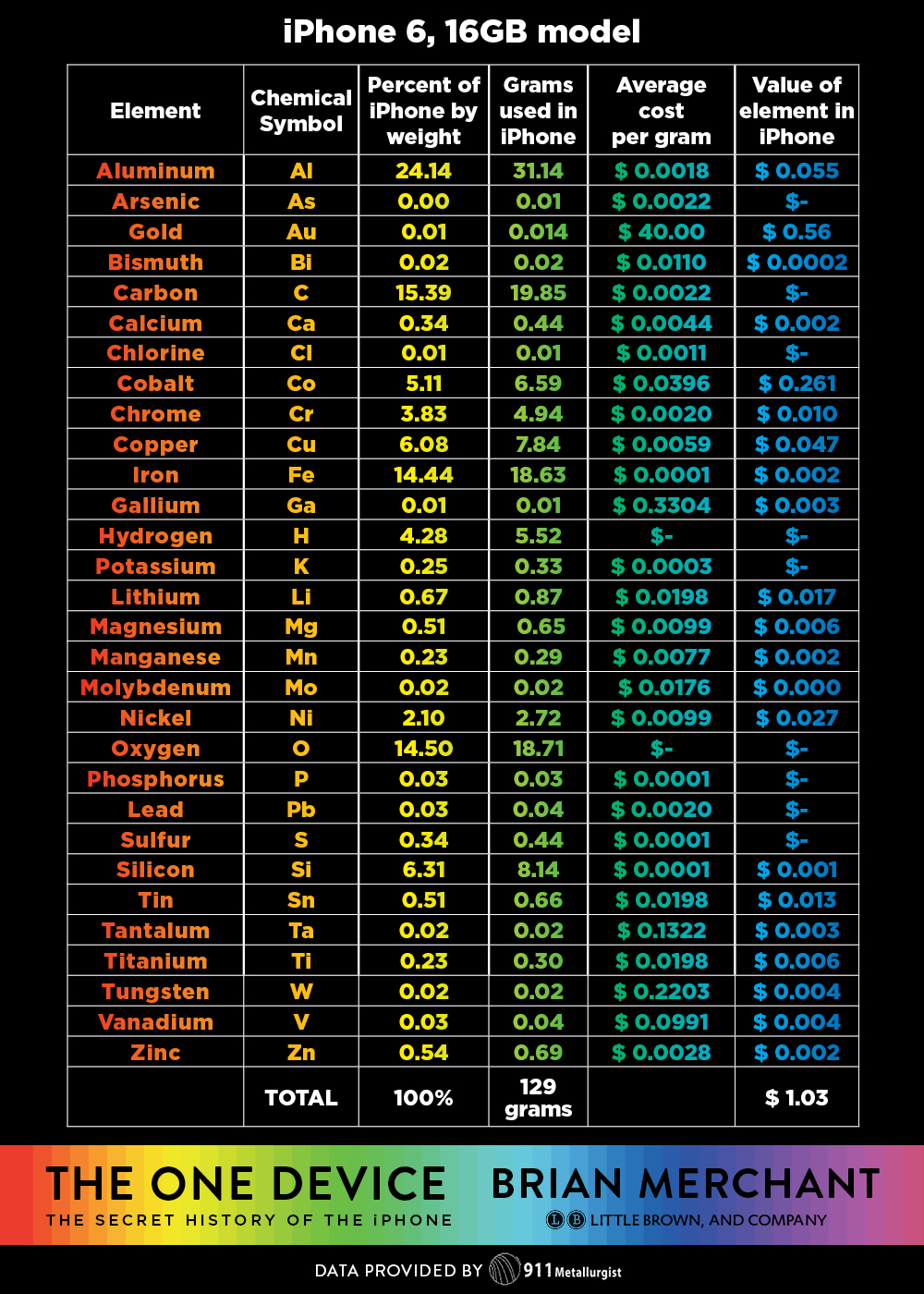

further blended and then pulverized,” Michaud’s report notes. After it was obliterated, it was time to look at the evidence. In his analysis of the experiment, Michaud writes, “aluminum and iron were the most abundant metals in the phone accounting for 38.5 percent of the iPhone mass. Other metals, such as copper, cobalt, chromium, and nickel accounted for 17.1 percent of the mass. Lithium was measured to be about 0.67 percent of the iPhone mass. Other elements of interest were carbon, at 15.4 percent, and silicon at 6.3 percent. There’s even a trace amount of arsenic in the phone, though not enough to be toxic.

Most of the phone was far from precious.

“It’s 24 percent aluminum,” Michaud says. “You can see the outside case as being aluminum. You wouldn’t think that the case weighs a quarter of the device … Aluminum is very light. It’s cheap; it’s a dollar a pound.”

The oxygen, hydrogen, and carbon used are associated with different alloys used throughout the phone. Indium tin oxide, for instance, is used as a conductor for the touchscreen. Aluminum oxides are found in the casing, and silicon oxides are used in the microchip, the iPhone’s

brain. Silicon accounts for 6 percent of the phone, the microchips inside. The batteries are a lot more than that: They’re made of lithium, cobalt, and aluminum.

There are indeed valuable metals locked away under the hood—something you hear about occasionally when talk turns to recycling phones—but there aren’t much.

“The iPhone 6 was found to contain 0.014 g of gold, 0.66 g (0.5%) of tin and 0.025 g of tantalum,” Michaud says. (That’s less gold than was in the iPhone 5, he notes, perhaps because as processors have shrunk and improved, they’ve used less of the precious metal.) “There were no precious metals detected in any major quantities, maybe a dollar or two,” Michaud says. “Nickel is worth nine dollars a pound and there’s two grams of it.” It’s used in the iPhone’s microphone.

And a lot of the precious stuff is difficult to get, and mined in places with little to no regulation and dangerous, even deadly conditions. The iPhone is .02 percent tungsten, for instance, which is commonly mined in Congo and used in vibrators and on the screen’s electrodes. Cobalt, a key part of the batteries, is mined in Congo too. Gold’s the most valuable metal inside the device, and there isn’t much of it.

And then, there’s the tin—an integral metal used in small amounts, especially in the solder that binds the components together.

*

Cerro Rico towers over the old colonial city of Potosí, Bolivia, like a giant dusty pyramid. You can see the “rich hill” from miles away as you wind up the highway to the city gates. The landmark also goes by a nickname: “The Mountain That Eats Men.” The mines that gave rise to both monikers have been running since the mid-1500s—that’s when freshly arrived Spaniards began conscripting indigenous Quechua Indians to mine Rico.

The Mountain That Eats Men bankrolled the Spanish Empire for hundreds of years. In the sixteenth century, some 60 percent of the world’s silver was pulled out of its depths. By the seventeenth century, the mining boom had turned Potosí into one of the biggest cities in the world; 160,000 people—local natives, African slaves, and Spanish settlers—lived here, making the industrial hub larger than London at the time. More would come, and the mountain would swallow many of them. Between four and eight million people are believed to have perished there from cave-ins, silicosis, freezing, or starvation.

“Cerro Rico stands today as the first and probably most important monument to capitalism and to the ensuing industrial revolution,” writes the anthropologist Jack Weatherford. In fact, “Potosí was the first city of capitalism, for it supplied the primary ingredient of capitalism—money. Potosí made the money that irrevocably changed the economic complexion of the world.” South America’s first currency mint still stands in its downtown square.

Today, Cerro Rico has been carved out so thoroughly that geologists say the whole mountain might collapse, taking Potosí down with it. Yet around 15,000 miners—some of them children as young as six years old—still work in the mines, prying tin, lead, zinc, and a little silver from its increasingly thin walls. And there’s a good chance that tin from Cerro Rico is inside your iPhone right now.

*

We didn’t last half an hour down there. Anyone with the stomach for it can glimpse the inside of this deadly mine, as enterprising Potosínos offer tours of the tunnels and shafts that make up the labyrinth under Cerro Rico. My friend and colleague (and translator) Jason Koebler—now the editor-in-chief of Motherboard—arranged for us to take the plunge.

Our guide, Maria, who also works as an elementary-school teacher, tells us that the tours go only to the “safe” parts. Yes, she said, many still die in the mines every year, but the last two, killed the week before we visited in July of 2016, were just kids who got drunk and got lost and froze to death. We shouldn’t worry, she says. Sure. The plan was to don hard hats, boots, protective ponchos, and headlamps and descend a mile or so into the mountain. Before driving us to the entrance, Maria stops at Miner’s Market, where we buy coca leaves and a potent 96 percent alcohol solution to give as gifts to any laborers we might encounter. Up top, the sun beats down hot but the air stings cold. Look out of the mine’s opening, past a cluster of rusty mine carts, and the city of Potosí is splayed out in the distance.

I’m nervous. Even if tourists spelunk here each week, even if children work here every day, this slipshod mine tunnel is still terrifying. Potosí is the highest-altitude major city in the world, and we are even higher than the city, at about 15,000 feet. The air is thin, and my breathing is short. One look at the splintery wooden beams that hold open the narrowing, pitch-dark mine shaft we’re about to walk down, one lungful of the sulfuric air, and my only impulse is to turn back.

*

Mining in Cerro Rico is a decentralized affair. The site is nominally owned by Bolivia’s state-run mining company Comibol, but miners don’t draw pay from the state; they work essentially as freelancers in loose-knit cooperatives. They gather the tin, silver, zinc, and lead ores and sell them to smelters and processors, who in turn sell to larger commodity buyers. This freelance model, combined with the fact that Bolivia is one of the poorest countries in South America, makes regulating work in the mines difficult.

That lack of oversight helps explain why as many as three thousand children are believed to work in Cerro Rico. A joint study conducted in 2005 by UNICEF, the National Institute of Statistics, and the International Labor Organization found seven thousand children working in mines in the Bolivian cities of Potosí, Oruro, and La Paz.

In 2008 alone, sixty children were killed in mining accidents at Cerro Rico. Maria tells us that the children work the deepest in the mines, in smaller, hard-to-reach places that are less picked over. It’s high-risk, boom-or-bust work, and children will often follow their fathers into the mine to supplement the family income or pay for their own school supplies. Mining is one of the most profitable jobs an unskilled laborer can find, due in part to the steep risks.

On a good day, these miners can make fifty dollars each, which is a hefty sum here. If they don’t manage to find any significant amount of silver, tin, lead, or zinc, they make nothing. They sell the minerals to a local processor, who will smelt small quantities on-site and ship larger amounts of ore out of the city to an industrial-sized smelter.

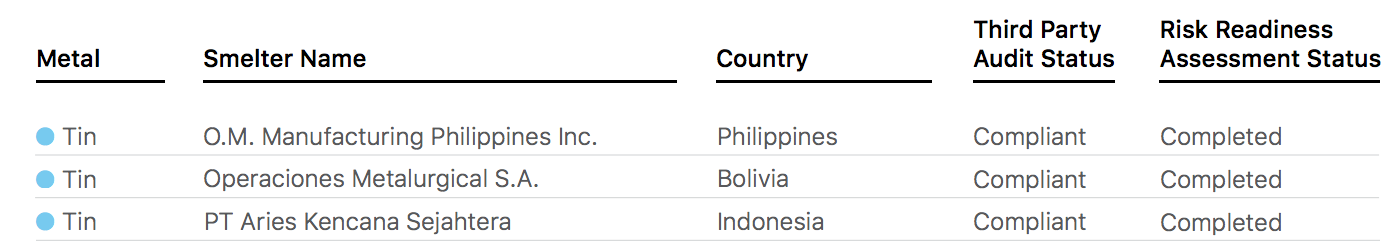

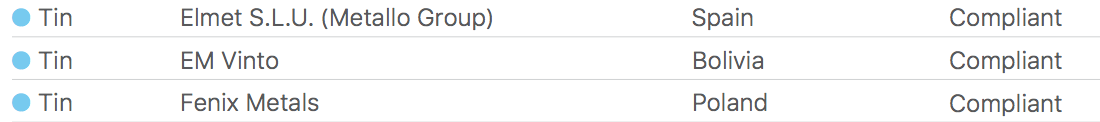

Silver and zinc are shipped to Chile by rail. Tin is shipped north to EM Vinto, Bolivia’s state-run tin smelter, or to Operaciones Metalúrgicas S.A. (OMSA), a private one. And from there, that tin can make its way into Apple products. “About half of all tin mined today goes to make the solder that binds the components inside our electronics,” Bloomberg reported in 2014. Solder is made almost entirely of tin.

So: metal mined by men and children wielding the most primitive of tools in one of the world’s largest and oldest continuously running mines—the same mine that bankrolled the sixteenth century’s richest empire—wound up inside some of today’s most cutting-edge devices. Which bankroll one of the world’s richest companies.

*

How do we know that there’s tin smelted at EM Vinto in Apple products? Simple: Apple said there is. Apple listed the smelters in its supply chain as part of the December, 2016 Supplier Responsibility report it made available to the public. Both EM Vinto and OMSA are on that list.

And I was able to confirm through multiple sources—through miners on the ground as well as industry analysts—that tin from Potosí does in fact head to EM Vinto.

“Indeed some tin does flow from Potosi,” Tom Mulqueen, the manager of statistics and market studies for the International Tin Research Institute, told me, though he notes that its share has declined somewhat in recent years. However, flows from the mines of Oruro and La Paz have increased, and UNICEF found thousands of child miners toiling there, too.

I first published the evidence linking Potosi miners to EM Vinto in a book, the One Device, from which much of this reporting is drawn, earlier this summer. Apple declined my numerous requests for on-the-record interviews during the reporting of that book, including a request to speak with Lisa Jackson, Apple’s Vice President of Environment, Policy, and Social Initiatives. However, I reached out yet again before publishing this update, and a spokesperson for Apple issued the following statement:

“Apple is deeply committed to the responsible sourcing of materials in our products. We require all tin, tantalum, tungsten, gold & cobalt smelters and refiners in our supply chain to participate in independent third party audits to assess and manage risks in their own operations. We work diligently to help our smelters and refiners identify labor, human rights and environmental risks in their operations. If they are unable or unwilling to meet our standards, we terminate business relationships. EM Vinto was removed as an Apple supplier of Tin solder earlier this year.” The spokesperson added that in 2016, “Apple terminated business ties with 22 smelters for their failure to meet our stringent standards.”

Apple declined to comment on the circumstances of EM Vinto’s recent removal—again, Vinto was listed not only as one of Apple’s stated tin suppliers, but as “compliant” by its third party audit system, in December 2016, its most recent supplier report—though Apple has a history of responding swiftly to unflattering reports. Regardless, unless your Apple device is brand new, it may contain tin mined at Cerro Rico.

And why does Apple list its smelters in the first place? Thanks to an obscure amendment to the 2010 Dodd-Frank financial-reform bill aimed at discouraging companies from using conflict minerals from the Democratic Republic of the Congo, public companies must disclose the source of the so-called 3TG metals (tin, tantalum, tungsten, and gold) found in their products. Apple says that it set about mapping its supply chain in 2010. In 2014, the company began publishing lists of the confirmed smelters it uses and said it was working to rid its supply chain of smelters buying conflict minerals altogether. (As of 2016, Apple had become the first in the industry to get all the smelters in its supply chain to agree to regular audits.)

This is no small feat. Apple uses dozens of third-party suppliers to produce components found in devices like the iPhone, and all of those use their own third-party suppliers to provide yet more parts and raw materials. It makes for a vast web of companies, organizations, and actors; Apple directly purchases few of the raw materials that wind up in its products. That’s true of many companies that manufacture smartphones, computers, or complex machinery—most rely on a tangled web of third-party suppliers to produce their stuff, which makes it difficult to draw direct lines from a specific device to a specific mine. But this system means most of our electronics—the iPhone included—begin with thousands of miners working in often brutal conditions on nearly every continent to dredge up the raw elements that make its components possible.

*

All of these elements, precious or abundant, have to be pulled out of the earth before they can be mixed into alloys, molded into compounds, or melted into the plastics that make up the iPhone. Apple does not disclose where its non-conflict minerals come from, but many sources have been reported over the years; here’s a quick sampling of how some of the crucial elements in the iPhone are mined.

Aluminum

Aluminum is the most abundant metal on Earth. It’s also, as we saw, the most abundant metal in your iPhone, due to its anodized casing. Aluminum comes from bauxite, which is often strip-mined, which, while not particularly dangerous to properly protected workers, is an operation that can devastate the natural landscape and imperil natural habitats. And it takes four tons of bauxite to produce one ton of aluminum, creating a load of excess waste.

Cobalt

Most of the cobalt that ends up in the iPhone is in its lithium-ion battery, and it comes from the Democratic Republic of the Congo. In 2016, the Washington Post found laborers working around the clock with hand tools in small-scale “artisanal” pits in DRC cobalt mines. They rarely wore protective gear, and the mines were almost totally unregulated. Child laborers toiled here too. “Deaths and injuries are common,” the investigation found. Apple promised to investigate the conditions after the news broke, and added cobalt to the list of conflict minerals for which it requires audits. Months later, when a subsequent story from Sky News caught actual footage of child miners digging out cobalt in the DRC, Apple announced it had suspended buying cobalt from all artisanal mines in the region.

Tantalum

In 2014, Apple announced that its tantalum suppliers were conflict-free. Tantalum was, for a long time, sourced largely from the DRC, where rebels and the army alike forced children and slaves to work in mines and used the mining profits to sustain their campaigns of violence. Mass rapes, child soldiers, and genocides have been bankrolled by the 3TG.

Rare Earth Metals

The iPhone’s hundreds of components require a suite of rare earth metals— such as cerium, which is used in a solvent to polish touchscreens and to color glass, and neodymium, which makes powerful, tiny magnets and shows up in a lot of consumer electronic parts—and mining these elements is a complex, sometimes toxic affair. Most rare earth metals come from a single place: Inner Mongolia, a semi-autonomous zone in northern China. There, the by-products from mining have created a lake that’s so gray, so drenched in toxic waste, that it’s been dubbed “the worst place on earth” by the BBC.

*

Michaud crunched the numbers to generate an estimate of how much earth had to be mined to create a single iPhone. Based on data provided by mining operations around the world, he determined that approximately 34 kilograms (75 pounds) of ore would have to be mined to produce the metals that make up a 129-gram iPhone. The raw metals in the whole thing are worth about one dollar total, and 56 percent of that value is the tiny amount of gold inside. Meanwhile, 92 percent of the rock mined yields metals that make up just 5 percent of the device’s weight. It takes a lot of mining—and refining—to get small amounts of the iPhone’s rarer trace elements, in other words.

A billion iPhones had been sold by 2016, which translates into roughly 34 billion kilos (37 million tons) of mined rock, according to Michaud’s calculations. That’s a lot of moved earth—and it leaves a mark.

Furthermore, extracting gold from a ton of ore typically requires about two and a half pounds (1,136 grams) of cyanide, Michaud says, as the chemical is used to dissolve and separate rock from precious metals. Because up to 18 of the 34 kilos of ore mined to produce each iPhone are mined in pursuit of gold, he says, it would require, on average, 20.5 grams of cyanide to free enough gold to produce an iPhone.

So, according to Michaud’s calculations, producing a single iPhone requires, roughly, mining 34 kilos of ore, 100 liters of water, and 20.5 grams of cyanide. “That’s what’s shocking!” he says.

*

Deep in a mine shaft at Cerro Rico, Marie, Jason, and I are ducking under collapsed support beams, checking out the mineral deposits in the rock seams, shining our headlamps down forks in the tunnel that look like they might never end. It’s deep-space black down here. Jason and I are both pretty tall and lanky. For stretches, the tunnel is only four feet high, forcing us to squat and waddle. The walls close in tight, and the air feels thick. Jason starts to get anxious. So I

start to get anxious.

Our guide takes the top off the bottle of moonshine we’ve brought as a gift for the miners and holds the bottle under our noses. It is indeed pretty efficient at delivering an ugly wake-up jolt.

A second later, my head hits the ceiling and a spill of sediment dusts my face. I’m taking video and blurry flash photos on my iPhone. The deposits on the walls— sulfur, maybe— are oddly beautiful.

Jason looks pale. I get it. The whole mountain is a ticking geological time bomb. It feels stupid to have this fear after a brief jog into a tunnel where thousands of people work every day, but here

we are. Still, I bet most iPhone owners would start to lose it if they had to spend more than twenty minutes down here. Jason wants to turn back. Before I know it, we’re winding back through the dark, and finally that little circle of light comes around a corner. Like I said: We didn’t last half an hour down there.

*

Those who have little choice but to work there every day typically suffer tragic consequences. Ifran Manene, a teenage miner turned tour guide, puts it bluntly to me later: Two of his friends are in the hospital right now. His father is sick. “Every year, we have more than fifteen miners die” in Cerro Rico alone, he says. And he tells me this without a trace of lament, like it’s perfectly normal. The sum of this human cost is difficult to comprehend, and there are stories like this taking place on almost every continent behind many of the dozens of elements in the iPhone.

Miners working with primitive tools in deadly environments produce the feedstock for our devices. Many of the iPhone’s base elements are dug out in conditions that most iPhone users wouldn’t tolerate for even a few minutes.

It’s not just Apple, of course. In fact, Apple is seen as better on transparency than some of its competitors, and Amnesty International has also singled out Samsung and Sony as also failing to combat child labor in their supply chains. Apple has paid lip service to ending its reliance on the ugly business of mining altogether, ostensibly by turning to recycling with projects like Liam, its iPhone-disassembling robot.

These are aspirational projects. The reality is that cash-poor but resource-rich countries will face an uphill struggle as long as there’s a desire for these metals—demand will continue to drive mining companies and commodities brokers to find ways to get them. These nations’ governments, like Bolivia’s, will struggle to regulate the industry, whose porous supply chains will allow vulnerable and desperate workers to enter them. Apple could, I’ve argued, do more to proactively set and enforce standards when it comes to mining, and take a harder line against violations of its own code of conduct—like the child labor it should be able to detect in its supply chain.

But for the foreseeable future, miners will continue to do backbreaking, lung-infecting labor to bring us the ingredients of the iPhone and smartphones everywhere. The iPhone deserves the credit it gets for revolutionizing mobile computing; for how it changed countless lives. Locked inside every one, alongside the fruits of unparalleled design and technological innovation, are trace amounts of human suffering. It’s an uncomfortable truth, maybe, but for now, it’s a part of what makes the one device possible.

Motherboard staff is exploring the cultural, political, and social influence of the iPhone for the 10th anniversary of its release. Follow along.