Injecting Gold Nanoparticles Into 3D Printed Materials Will Protect Them From Hackers, Study Says

Credit to Author: Jacob Dubé| Date: Wed, 16 Aug 2017 04:00:00 +0000

3D printing has been slowly finding its home in industries that require lots of specialization. In medicine, for example, 3D printing—also called additive manufacturing—has been used to create artificial organs that actually bleed when they’re cut (implanting these into human patients is still a ways off). The tech could be used to lower costs in construction, too.

But as additive manufacturing is used in more fields, hackers will naturally be interested in locating weaknesses. Last year, researchers sabotaged the printing of a drone propeller, which caused it to malfunction and crash two minutes after takeoff.

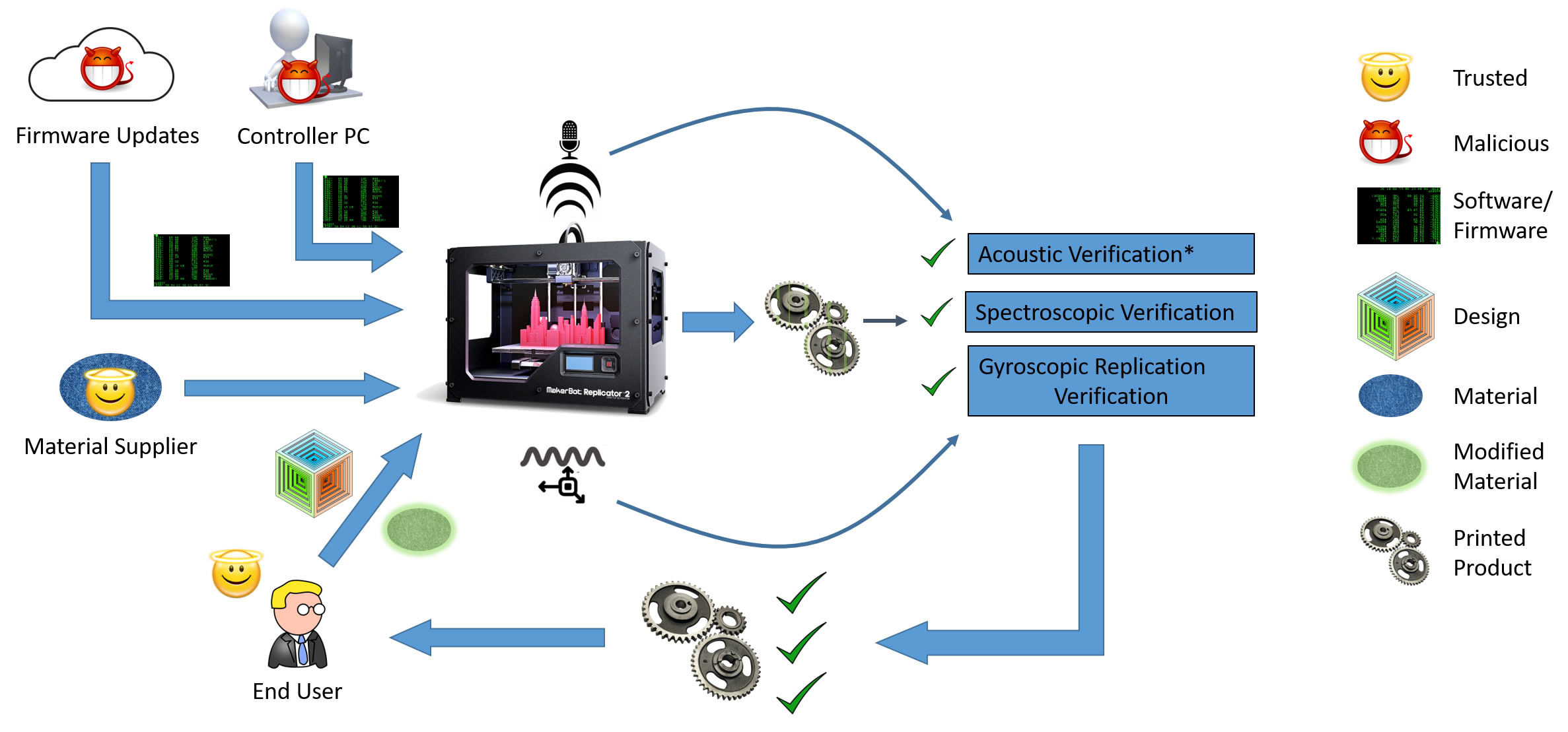

A new study presented Wednesday at the USENIX Security Symposium in Vancouver offers some solutions to ensure that your next 3D-printed design isn’t rotten on the inside. They include monitoring the sounds and movements of the printers for inaccuracies, and injecting gold nanoparticles into the filament to make sure everything goes where it’s supposed to.

The paper describes how researchers acquired several 3D printers—a Lulzbot Taz 6, Lulzbot Mini, and an Orion Delta—and were able to hack the firmware and print defects inside whatever they were creating. In many cases, it would be hard (if not impossible) to notice these flaws once a product is fully printed, although it might be left structurally vulnerable.

Anti-hacking security software is important, according to the paper, but isn’t completely foolproof. Other studies have suggested disconnecting 3D printers from the internet and encrypting the design files could prevent software hacks, but these study authors, who are based at Rutgers University-New Brunswick and Georgia Institute of Technology, present three methods that rely instead on physically verifying the printed materials for defects.

Read More: The Man Who Scared the World With 3D Printed Guns Isn’t Going Anywhere

The first involves creating an audio recording of a printer working on a model, and comparing the sound file to an existing recording of the same model that was made during another printing job. If the files don’t match up with an appropriate “confidence score,” it means that the model has been tampered with. The second method is similar: movements of the printer are monitored and compared to an existing example to ensure they’re the same.

The final method described in the study involves injecting gold nanoparticles in the filament used to make the materials. Once a 3D printed object is delivered to whoever ordered it, that person would be able to scan the object to verify that the nanoparticles are in the correct places. If the printed model was tampered with, the nanoparticles would have moved.

Insecure 3D printers will be an even larger problem as more people outsource 3D printing to independent companies to save money, according to co-author Mehdi Javanmard of the Rutgers School of Engineering.

“Imagine outsourcing the manufacturing of an object to a 3D printing facility and you have no access to their printers and no way of verifying whether small defects, invisible to the naked eye, have been inserted into your object. The results could be devastating and you would have no way of tracing where the problem came from,” said Javanmard in a statement. Motherboard reached out to the study authors for comment, but didn’t hear back before publication.

The methods discussed in the paper can help find inconsistencies as they happen and potentially save hours of time that would be wasted on finishing the defective models. This would be especially helpful if identical objects were being printed on an industrial level, the study said. As well as, you know, making sure that your artificial 3D printed heart doesn’t have a hole in it, or double checking that your 3D printed roof won’t collapse. Just to be safe.

Get six of our favorite Motherboard stories every day by signing up for our newsletter.

https://motherboard.vice.com/en_us/rss